A look in to the depth of a well - DOWNHOLE POSITION SENSOR

A NEVER-BEFORE SEEN GLIMPSE INTO TO THE DEPTH OF THE WELL

By Benjamin Eilan

Ormat engineers has been developing a new sensor to easily operate production pump in wells that are consider extremely challenging.

One of the main challenges in the operation and commissioning process of a deep geothermal line shaft pump is the differential movement between rotating and stationary parts.

Production pump are designed with extra axial play, meaning, they can tolerate more differential movement between rotating and stationary parts before an impact occurs.

However, in some cases even this extra axial play is not enough, and an impact between rotor and stator occurs, in what is called "topping" or "bottoming". This kind of impact can end in a very costly catastrophic failure, in some cases, only a few minutes (!) after a pump has been commissioned.

To answer this challenge, Ormat has developed and patented a novel downhole position sensor which tracks the rotor's relative position in real time, enabling operations teams to perform all commissioning and operations with a never-before seen glimpse into to the depth of the well.

Ormat has been developing and testing this sensor over the last few years, and with its aid – easily operating production pump in wells that were previously considered extremely challenging.

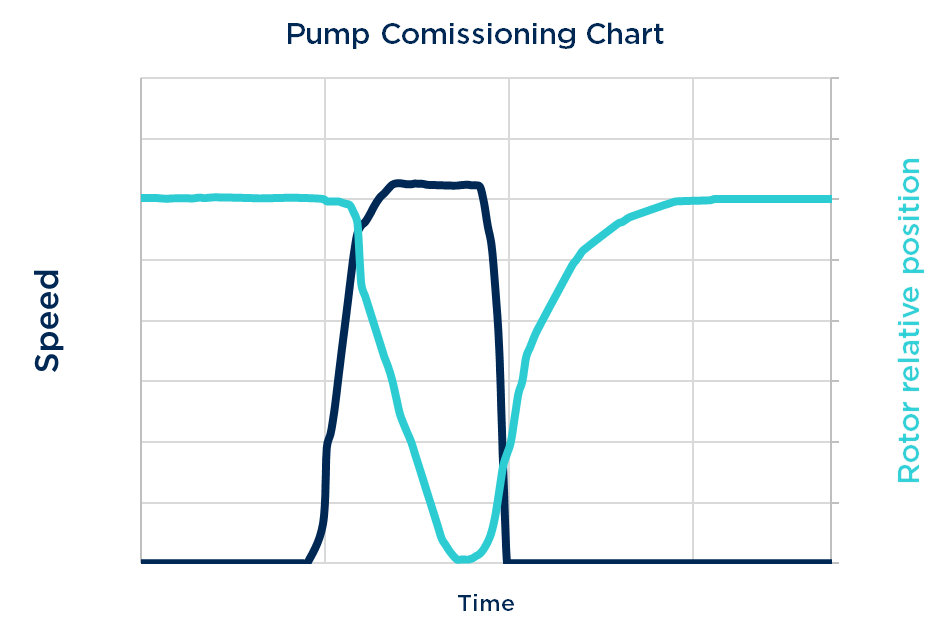

The chart below illustrates this sensor's contribution: a startup of a deep pump was attempted, but the position sensor alerted that the impellers were dangerously close to contacting the bottom of the bowls, so the pump was immediately stopped, it's spacing was readjusted, and it has been running ever since.